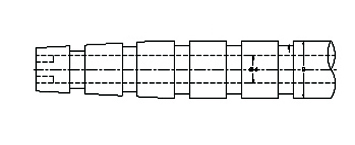

| D FENDERS – DD TYPE | |||||

|

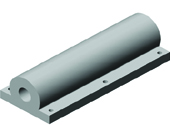

DD FENDERS are most widely used fenders around

the world for application like protection tug boats, small jetties and wharfs. Various sizes available DD50,DD75,DD100,DD125,DD150,DD200,DD250, DD300,DD400,DD450, DD500 and other sizes can |

|

|

|||

| DO FENDERS | |||||

|

DO fenders are very popular in the new vessel

building industry due to ease fixing these fenders in the sides of the vessels without drilling on the vessel shell. various sizes available DO100,DO125,DO150,DO175,DO200, DO250,DO300, D0350,DO400, DO450,DO500 and other sizes can supply as per customer requirement. |

|

||||

|

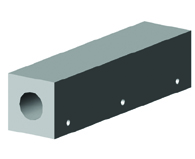

SQUARE FENDERS

|

|||||

|

SQUARE FENDERS present a popular alternative to D type fenders where a more heavy duty performance is

required. These fenders can be mounted on boats and tugs in straight as well as curved form. Holes for fixing the fenders can be drilled as per requirement.These fenders classified in to two types |

|||||

|

SO FENDER

|

|||||

|

Available sizes SO200, SO250, SO300, SO350, SO400,SO450,SO500.

|

|||||

|

|||||

|

SD FENDER

|

|||||

|

Available sizes SD200,SD250,SD300,SD350,SD400,SD450,SD500

|

|||||

|

Other sizes supplied as per customer’s requirements.

|

|

||||

|

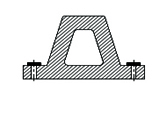

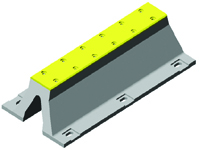

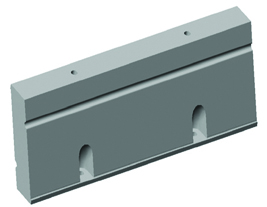

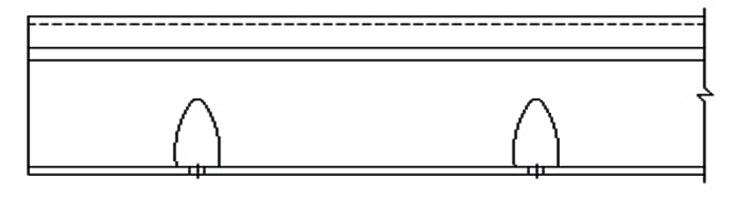

SQUARE FENDERS KEY HOLE TYPE

|

|||||

|

With key hole shaped inner bore have the flexibility to adjust the width to enable easy fixing. The fenders are

mainly used for pushing large vessels; it can also be installed on curved structures and round corners.Available sizes –SQK200, SQK250, SQK300, SQK35O and other sizes as per customer requirements. |

|||||

|

|

|

||||

|

CYLINDRICAL BOW & AFT FENDERS

|

W FENDERS

|

||||

|

These fenders can be mounted using chain passing thro’ the

centre hole and supported by nylon straps or chain passing thro’ the grooves. It is recommended to use chains covered with rubber hose in the grooves. |

Alternative to square fenders and are easy to install.

|

||||

|

|

||||

|

|||||

|

WING FENDERS

|

|||||

|

Easy installation on vessels

and concrete structures .using small jetties, pleasure crafts,pilot boats,barges and tug boats.Available sizes – 4’’ ,6’’, 8’’ , 10’’, 12’’ , 14’’ , 16’’ and other sizes as per customer requirements. |

|

||||

|

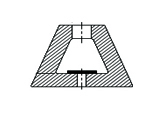

TRAPEZOIDAL FENDERS

|

|||||

|

Wing type

|

Closed type

|

||||

|

|

|

|

||

|

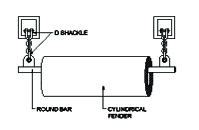

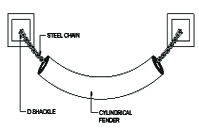

CYLINDRICAL FENDERS

|

|||||

|

This is the most popular fender system

around the world due to their simple construction and easy installation. Small outer diameter for use by a small boats and big outer diameter for use by a oil super tanker . The fenders can be installed horizontally or vertically. |

|

Size outer diameter starts

from 100 mm to 2100mm and inner diameter starts from 50 mm to 1250 mm. |

|||

|

|

||||

| ARCH FENDERS | VA TYPE | ||||

|

Can be used for small marinas with non marking type VLA fenders

for luxury yatches and GRP vessels. Arch fenders with UHMW PE facing also useful where the vessel continues to move perpendicular to the fender after berthing thereby inducing shear stresses on thefender. |

|

||||

| VLA TYPE | |||||

|

|

|

|||

| CELL FENDERS | |||||

|

This is designed based on the axial loading performance of cylindrical fenders with steel embedded within

the rubber. Cell fenders can be used a single fender or combination of more fenders fixed to one steel facing panel. Cell fenders can be used only by using steel panel to reduce the face pressure acting on the hull of the berthing vessel. |

|||||

|

|

||||

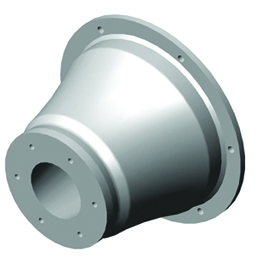

| CONE FENDERS | |||||

|

CONE FENDERS are the latest version of fenders developed based on the cell fenders, but increased

deflection and high energy absorption. Cone fenders have to be used along with steel facing panel fitted with UHMW PE pads. |

|

||||

|

ELEMENT LEG FENDERS

|

|||||

|

ELEMENT LEG FENDERS are unique type of fenders

in view of their construction, manufacturing process and performance. These fenders have a law reaction force and high energy absorption characteristic. Each size of element leg fender is available in different lengths as well as different grades to provide solution for most fender requirements. |

|||||

|

|

||||

|

|||||